Semiconductor cleaning process analysis: FerroTec chiller how to effectively improve the efficiency and precision of cleaning

01 Semiconductor cleaning process

In the semiconductor manufacturing process, accompanied by the generation of many impurities, these impurities will affect the yield, electrical performance and reliability of the chip. Cleaning process is designed to remove ultra-fine particulate contaminants, metal residues, organic residues left over from the previous process in chip manufacturing, and remove photoresist mask or residues. Wet etching of thin film materials such as silicon oxide, silicon nitride or metals can also be performed as needed to prepare excellent surface conditions for the next process.

As semiconductor manufacturing processes continue to advance, the control of contaminants on wafer surfaces is becoming more and more demanding. Before and after almost every process in semiconductor manufacturing, surface impurities need to be removed through the cleaning process to ensure the cleanliness of the wafers. For example, a 90nm chip requires a cleaning process of 90 channels, a 20nm chip requires a cleaning process of 215 channels, cleaning accounts for about 30% of all semiconductor process steps.

02 Mainstream technology route - wet cleaning

The cleaning process runs through the three major processes of wafer manufacturing, wafer manufacturing and packaging. Diffusion, deposition, injection and other processes before and after the need for cleaning, each step of the cleaning requires different equipment, chemical liquid formula, process conditions to complete. According to different cleaning media, semiconductor cleaning technology is mainly divided into wet cleaning and dry cleaning of two kinds.

Wet cleaning uses specific chemical solutions and deionized water to remove impurities on the wafer surface through chemical reactions. Dry cleaning does not rely on chemical reagents, mainly using plasma cleaning and other technologies. Wet cleaning is currently the mainstream technology route, accounting for more than 90% of the number of chip manufacturing cleaning steps.

03 Wet cleaning in the commonly used chemical solutions

Wet cleaning cleaning solution used mainly sulfuric acid cleaning solution, SC1 cleaning solution, SC2 cleaning solution and other chemical solutions.

1、sulfuric acid cleaning solution: sulfuric acid and hydrogen peroxide mixture, the concentration ratio of 5:1, reaction temperature of 125 ℃. Used to remove photoresist residues or organic matter on the wafer surface. The reaction mechanism is:

H₂S0₄+H₂0₂ → HO-(SO₂)-0-0H+H₂O

HO-(SO₂)-0-0H+-(CH₂)n → CO₂+H₂

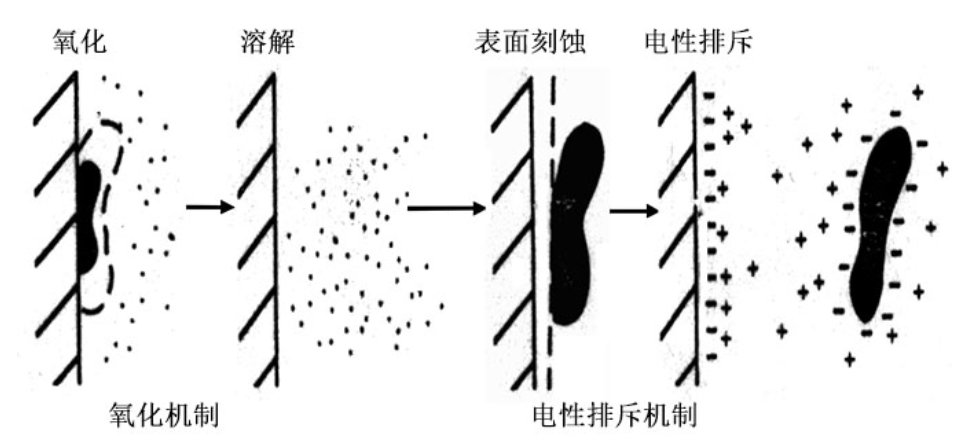

2、SC1 cleaning solution: ammonia, hydrogen peroxide and water mixture, the three volume ratio of 1:2:50. its reaction temperature of 25 ℃, used to remove particles on the wafer impurities and polymers. The cleaning mechanism is oxidation and electrical repulsion, as shown in the figure:

3、SC2 cleaning solution: hydrochloric acid, hydrogen peroxide and water mixture, the three volume ratio of 1:1:50. SC2 cleaning solution's main function is to remove metal ions on the chip. The cleaning mechanism is to provide a low pH environment, so that alkaline metal ions, metal hydride can be dissolved in the SC2 cleaning solution.SC2 cleaning of the relevant chemical equation is as follows:

Si+H₂0₂ → Si0₂+H₂0 Zn+HCl → ZnCl₂>+H₂

Fe+HCl → FeCl₂+H₂ Mg+HCI → MgCl₂+H₂

04 FerroTec chiller in the semiconductor cleaning applications

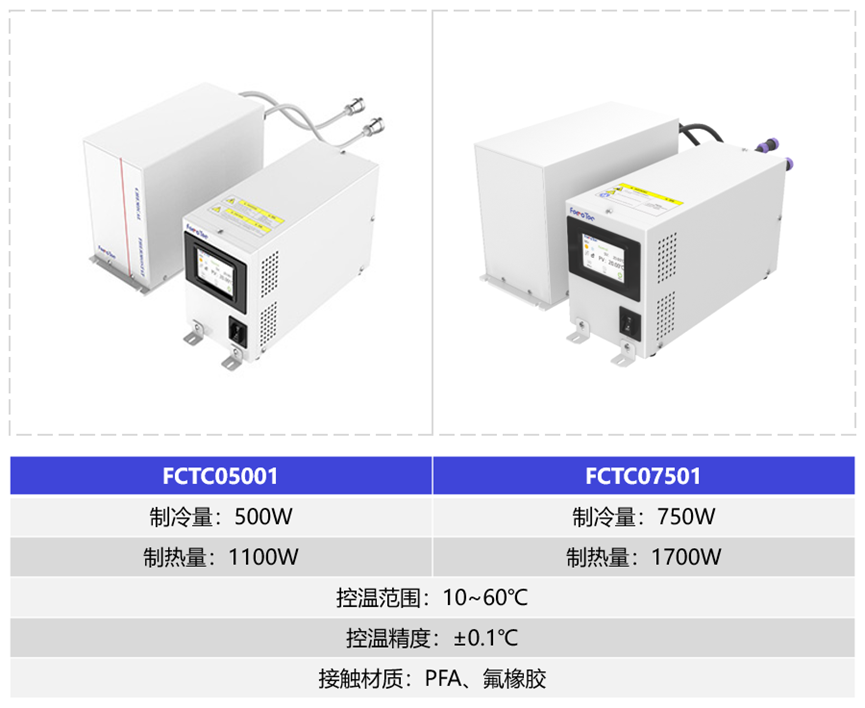

Semiconductor cleaning is affected by a variety of factors, among which, the solution temperature, concentration, granularity, etc. will affect the cleaning effect. Within a certain range, the higher the temperature, the more intense the chemical reaction of the cleaning solution, the more thorough the wafer cleaning effect. FerroTec independent research and development and production of special liquid series chiller, with high purity core, corrosion resistance, rapid heat transfer, low impedance and other advantages. The core contact parts are made of PFA, which can better control the temperature when the chemical cleaning liquid is mixed and other environments, and realize precise temperature control. Compared with similar products, the cooling power is larger and the cooling speed is faster.

Technical Performance Advantages

01 High precision temperature control

Semiconductor cleaning process requires high temperature stability (usually within ± 0.1 ℃), FerroTec chiller using PID intelligent algorithms and high efficiency inverter technology, combined with highly sensitive sensors, the temperature control accuracy is better than most competitors (such as some of the European and American brands standard ± 0.3 ℃), to meet the demanding needs of the advanced process (such as the following 14nm).

02 Corrosion resistance and material compatibility

For the semiconductor cleaning of strong acid (such as HF, H2SO4), strong alkali (such as NH4OH) and organic solvents, FerroTec chiller using titanium alloy heat exchanger, PFA sealing materials, etc., compared with competing products (such as some domestic manufacturers use 316L stainless steel), corrosion resistance is stronger, the life of the equipment to extend the more than 30%.

03 Low flow fluctuation design

Through the optimization of the pump group and pipeline design, the flow rate fluctuation is <2%, which is better than the common industry level of 5%. Ensure stable liquid flow during wafer cleaning, reducing the risk of wafer surface defects.

Customization and Integration Capability

01 Modular Design for Multiple Scenarios

FerroTec provides a full range of chillers from small laboratory equipment (5kW) to large-scale mass production lines (500kW or more), and supports modularization combinations (e.g., parallel redundancy of multiple machines), which is more flexible than European and American brands.

02 In-depth cooperation with industry-renowned cleaning machine manufacturers

FerroTec's long-term joint development with domestic semiconductor equipment vendors (e.g. Semiconductor, Beifang Huachuang) realizes the seamless connection between chiller and washer control system, which reduces the third-party integration and debugging time (compared with the imported brands to shorten the delivery cycle by 50%).

Localized Service and Cost Advantages

01 Fast response and spare parts supply

There are more than 10 service centers in China, providing 24-hour technical support, fault response time <4 hours, while European and American brands usually take more than 48 hours (spare parts rely on imports).FerroTec chiller localization rate of 80%, the cost of spare parts is only 60% of imported brands.

02 Outstanding comprehensive cost performance

Under the same performance (e.g. temperature accuracy, corrosion resistance level), the price of FerroTec chiller is about 70% of Japanese competitors, 50% of European and American brands, and the energy consumption ratio is optimized by 10%-15% (adopting high-efficiency magnetic levitation compressor technology), which results in lower long-term operation and maintenance costs.

Industry Certifications and Compliance

01 SEMI Certified and Cleanroom Compliant

FerroTec chillers are certified to SEMI S2/S8 safety standards and support Class 1 cleanroom environments (low particle/vibration design). Their performance is comparable to that of Japanese brands (e.g., SMC), but they are more adaptable to China's local environmental regulations (e.g., GB/T 18430 energy-efficiency standards for chillers).